1. Report preparation standard

"The Quality Integrity Report of Shuangda Valve Co., Ltd." reviews Shuangda Valve Co., Ltd.'s concepts, systems, measures and results in quality management, product quality responsibility, and quality integrity management. Regarding the disclosure content of this report, the description is as follows:

(1) Scope of report

Organizational scope of the report: Shuangda Valve Co., Ltd.

Time frame of the report: January 2018 to December 2018 Report release cycle: This report is an annual report

(2) Statement on the objectivity of the report content This report is compiled entirely based on the actual production and operation conditions of the company, the content is objective and fair, and there is absolutely no false information. It is published regularly to accept supervision and guidance from the society.

2. Speech by the general manager of the company

Dear government quality supervision department, friends and colleagues from all walks of life:

Shuangda Valve Co., Ltd. sincerely appreciates the love, support and cooperation of users from all walks of life! Our company has advanced production technology and equipment, has established a strict quality control system and a complete after-sales service system, and is committed to developing into a world-leading and even leading, integrating design and development, manufacturing, installation, sales and service. Large-scale specialized valve manufacturing enterprises in Zhejiang and Shanghai.

The company always adheres to the concept of "quality first", adheres to the mission of "innovating for education and escorting health", adhering to the values of "responsibility, dedication, and gratitude", and continues to provide users with environmentally friendly, safe, high-performance, and reliable Quality products.

Since its establishment, the company has received the care and help of leaders at all levels and friends from all walks of life, and has received valuable support from distribution agents and suppliers. Here, on behalf of all employees of the company, I would like to care and support the development of our company. All the leaders, friends from all walks of life and all new and old customers express their most sincere thanks!

3. Company profile

Shuangda Valve Co., Ltd. has specialized in the valve industry for more than 20 years. It is a high-tech and innovative enterprise integrating product design, R&D, manufacturing, sales and service, and a key backbone enterprise in the valve industry. The company was established in 2000 with a registered capital of 125.8 million yuan. It covers an area of 15.1 mu, with a construction area of 147.76 million square meters. There are 76 employees, 15 engineering and technical personnel, including 8 senior engineers. It is a member of the state power company parts supply network, a designated production unit of China National Chemical Equipment Corporation, a member unit of China Petrochemical Resources Market, a member unit of China's oil and gas first-level supply network, a member of China City Gas Association, and it has obtained the recommended product certificate of China Engineering Construction Association. , Recommended product certificate of Water Supply and Drainage Equipment Branch of China Construction Metal Structure Association.

Since its establishment, the company has hired senior valve experts and introduced core technologies in the valve field. Relying on human resources, technology, equipment, information, management, and team spirit, after 20 years of trials and hardships, we have ushered in the present glory.

In today's increasingly integrated world economy, the company has built both competitive and economic benefits-the company's products cover a variety of series of ball valves, butterfly valves, gate valves, globe valves, check valves, American standard valves, stainless steel valves, fixed Ball valves, three-way and four-seal ball valves, four-way and four-seal ball valves, forged steel valves, throttle valves, regulating valves, flat gate valves, hydraulic control valves and other special valves and many other specifications. Put on the market high-tech products such as intelligent control, product serialization, multi-level functions, large-scale specifications, environmental protection and energy saving. Products have been exported to dozens of countries and regions in the Middle East, Southeast Asia, Europe and the United States, and have made great contributions to domestic petrochemicals, metallurgical fertilizers, electric power pharmaceuticals, municipal construction, fire and heating, water supply and drainage, pollution control and other industries and large and small projects. Relying on the products' high quality and price, service first, honesty and friendliness, they have won frequent praises and favors from domestic and foreign users, and they come here with admiration.

The company relies on scientific and technological innovation and actively applies new technologies, new materials and new processes to research, develop and manufacture high-quality valve products, and establish a corporate image of Shuangda. Relying on the standardized operation of IS9001, API, CE, AZ and other quality management systems and foreign advanced standards, the implementation and realization of standardized production of products.

The valve body material adopts WCB/A105, WC1, WC9, ZGCr5MoZGCr5Mo1V, CF8/304, CF8M/316, CF3/304L, CF3M/316L, 12CrMoV, ZGCr18Ni9Ti, ZG1Cr18Ni12Mo2Ti, etc. The sealing surface adopts wear-resistant and high-temperature resistant Stellite (Stellite ) Cobalt-based cemented carbide materials. The driving modes are manual, gear transmission, electric, pneumatic and hydraulic; the valve diameter ranges from 10mm~2200mm and 1/2 "~32"; the working pressure ranges from 1.0~42MPa and 150~3500Lb; the working temperature is -196℃~650℃, Products are widely used in power systems, petroleum, chemical, metallurgy, mining, medicine and other industries. Valve products enjoy a high reputation throughout the country for their excellent quality, and sales offices have been set up throughout the country. Bring you the guarantee of quality with leading technology and management, and repay the majority of users with a good reputation

The love of Shuangda valve series. Adhering to the business philosophy of "all for customer satisfaction", we will continue to apply new technologies, new processes, new materials, actively develop new varieties, and improve quality. With the company's strong technical force and professional production division advantages, we will provide customers with With better valve products and better after-sales service, we are striving to establish a modern valve enterprise.

Shuangda Valve Co., Ltd. solemnly promises to new and old customers: Shuangda Valve will cooperate with new and old customers to create brilliant future with more advanced technology, more reliable quality, lower price and faster delivery time.

Enterprise Quality Integrity Report

1. Corporate Quality Concept

The company adheres to the concept of "people-oriented, honesty as good, advancing with the times, and win-win cooperation". Quality is the foundation of a company's entrepreneurship and the foundation of an enterprise. Strengthening quality awareness and implementing quality responsibility are the primary tasks for implementing the quality concept. Whoever produces is responsible, who benefits and who bears responsibility is a basic concept that must be widely promoted and implemented throughout the company. In particular, operators and managers must take the initiative to establish quality awareness and take the initiative to take responsibility for quality.

2. Quality Management

2.1 Quality Management Organization The general manager of the company personally presides over the investigation, discussion and formulation of the quality-centric business strategy. The company’s vice president and management representatives are fully responsible for the company’s product quality and safety work, organize the formulation of corporate quality development strategies, annual quality work plans and quality safety assurance measures; establish and implement advanced quality management systems and management methods; organize the implementation of quality improvement, Mass quality activities such as quality tackling; assign corresponding personnel and stipulate their responsibilities, authorities and relationships to ensure that the quality management system is established and maintained, and to promote continuous improvement.

The quality management organization chart is as follows:

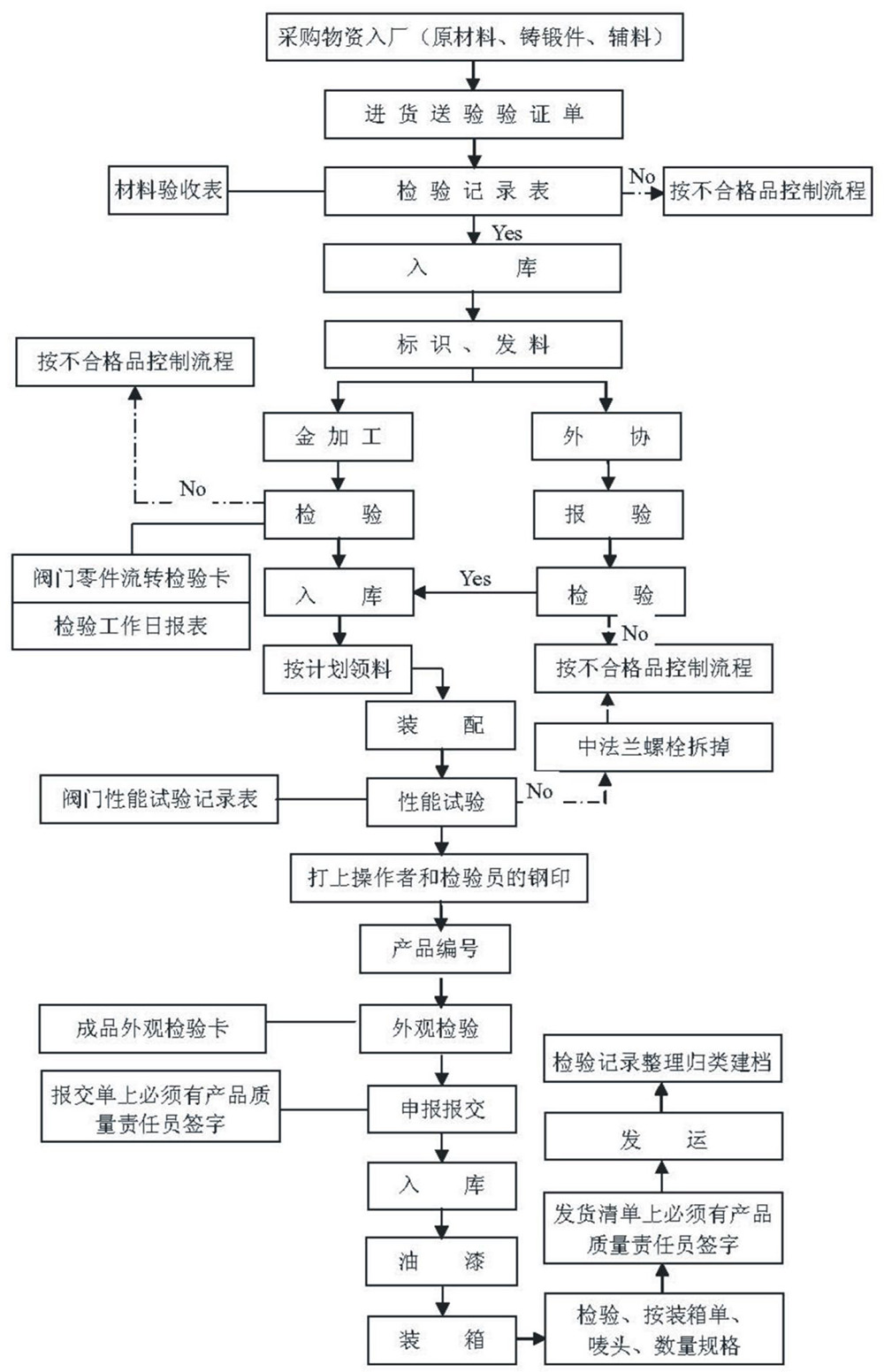

质量控制检验流程图:

2.2 Quality Management System

Quality is the life of an enterprise. From the first day of production of steel ball valves for petroleum, petrochemical, natural gas and related industries, the company's general manager regards product quality as the first major issue. In the quality management work, we are farsighted and formulate quality policies and quality goals that are in line with the actual development of the enterprise. Striving to be the best, only better, to produce high-quality goods with meticulousness, to cast quality with professionalism, and to always pursue better quality to win customers' value satisfaction. The company has successively passed many certifications such as the ISO9001 quality management system. The top leaders of the company pay attention to customers, pay attention to product quality and the maintenance and improvement of the system, and the quality awareness of employees is generally high. The company’s leaders pay attention to the construction of infrastructure, and invest in the purchase of production and testing equipment and the transformation of related facilities year by year; at the same time, it recruits sufficient professional and technical personnel to enhance the ability to guarantee scientific research and production, and the allocation of resources meets the current needs of scientific research and production. In daily practical work, the system is constantly perfected, updated and improved, and the annual internal audit and management review of the system are carefully organized and deployed, and the system is continuously improved through the annual internal audit, management review and external supervision and review. , To ensure the adequacy and effectiveness of the operation of our company's quality management system, and to ensure the quality of the products.

3. Enterprise Quality and Integrity

3.1 Quality and Integrity Management

As an enterprise, the premise of sustained and healthy development is law-abiding operation, honesty and trustworthiness. The reason why Shuangda products have a good reputation and can withstand the consideration of time is entirely due to our company's integrity management. For many years, the company has been carrying out production and operation with a high sense of responsibility to consumers and employees. From the management to the front-line employees, we always adhere to product quality first and regard quality as the life of the company. We strictly follow national standards and relevant laws and regulations in terms of design and development, procurement, production process control, product testing, and after-sales service. , Realize the follow-up monitoring and management of the whole process from design and development-purchase-production-after-sales, so as to provide customers with products that meet their needs and expectations.

The company publicizes the company's values of "responsibility, dedication, and gratitude" to all employees through education and training, distribution of "employee manuals" and other forms.

3.2 Quality culture construction

Quality culture is an important part of corporate culture, and it is a comprehensive manifestation of the purpose, concept and moral code of conduct pursued by the company in terms of quality. The core competitiveness of modern enterprises is not products and services, but excellent corporate culture.

The company has formed a good atmosphere in which everyone cares about quality and creates a brand with everyone's responsibility. The company has also carried out a wide range of lively quality awareness activities to accelerate the transformation of all employees’ outdated quality concepts, enhance employees’ sense of competition and sense of responsibility, firmly establish a dedication to work among employees, and pursue to meet customer requirements. Employees always warn themselves in their positions. The entire process of product realization design and development, procurement, production, inspection, and after-sales service. Every step of your operation and decision directly affects the quality of the product and the market reputation of the product. Therefore, strict quality control has become the consciousness of employees. The improvement of quality awareness has made all employees enthusiastic about participating in quality management.

In the construction of the quality culture, the company not only does a good job in the construction of the data system, strengthens its own technical strength, and improves the core competitiveness, but also attaches great importance to the education and training of the employees. According to the needs of employees in each position, the company shall formulate detailed employee training plans and organize the implementation every year. If the department submits training applications according to the needs, it will also try its best to arrange. Training methods are also diverse. We hire engineers from inside and outside the company to give lectures, constantly update knowledge and skills to keep up with the ever-evolving society and market, and at the same time evaluate the effectiveness of training. In addition to hiring or introducing some external talents, the company pays more attention to discovering and cultivating talents from within. It dares to discover and promote technical and management talents from front-line employees, not only by looking at diplomas, but also by level, and paying attention to the combination of new and old, and bringing the new with the old. Maintain the vitality and continuity of the team. Through years of training and adjustment, the company's existing management and technical talents are distinct, and key positions have formed a good echelon, laying a foundation for the sound development of quality management.

Fourth, the foundation of enterprise quality

4.1 Enterprise product standards

In accordance with customer requirements, our company actively adopts national standards and foreign standards in the design and manufacturing process, such as the adoption of International Organization for Standardization (ISO), national standards (GB), industry standards, etc., which greatly improves the quality of products and promotes the company The development of domestic and foreign markets.

The company is a governing unit of China Valve Association; a member of China City Gas Association; a standing governing unit of China Construction Water Supply and Drainage and National Water Supply and Drainage Technology Information Network; a member of the first-level supply network of State Power System, China Petroleum and Natural Gas, Sinopec Materials and Resources, China Chemical Equipment The head office and Sinopec Group are designated and recommended companies for products. At the same time, the "Relevant Party Needs and Expectations Control Procedures", "Risk and Opportunity Control Procedures", "Environmental Factors Identification Evaluation Control Procedures", "Hazard Source Identification, Risk Assessment and Control Planning Procedures", "Laws and Regulations Management and Compliance" were formulated at the same time. Evaluation Control Procedures, Target Indicators and Management Plan Procedures, Infrastructure and Environmental Control Procedures, Energy and Resource Management Procedures, Monitoring and Measuring Equipment Control Procedures, Organizational Knowledge Control Procedures, Human Resources Resource Control Procedure, Information Communication Control Procedure, Document and Record Control Procedure, Customer Complaint Control Procedure, Order Review Control Procedure, Emergency Preparedness and Response Control Procedure, Procurement Control Procedure, Production Process Control Procedures, Identification and Traceability Control Procedures, Accidents, Incidents and Non-conformance Management Procedures, Environmental and Occupational Health and Safety Performance Monitoring and Measurement Control Procedures, Internal Audit Management Procedures, Management Procedures Review control procedures", "correction, prevention, improvement control procedures" and other management documents.

4.2 Enterprise measurement level

The monitoring and measuring equipment shall be sent to a department with verification or calibration qualifications for calibration or verification according to the specified requirements, or be compared with the measurement standards that can be traced to the international or national standards, and the company shall organize the calibration according to the prescribed time and procedures. Clearly mark the calibration or verification status, and keep the calibration or verification records.

4.3 Certification and accreditation

The company has successively passed the ISO9001 quality management system, ISO14001 environmental management system, OHSAS18001 occupational health and safety management system, etc. These certifications ensure the high quality of products, maintain a clean and pollution-free production environment, and ensure the occupational health and safety of employees. Comprehensively improve product quality and ensure the specifications and standards of various production and operation activities.

Figure 4-1 Authentication certificate

4.4 Enterprise inspection level

The company strictly implements the "Measurement Law of the People's Republic of China" and other documents and regulations, and has established the "Monitoring and Measuring Equipment Control Procedures". There are full-time metering personnel responsible for the company's in-use metering equipment management, equipment and regular inspections. At the same time, the company has strengthened the professional training of measurement management personnel, which provides a strong guarantee for the standardization and standardization of the company's measurement management.

The company's measuring instruments are equipped according to customer requirements and inspection standards. At the same time, a complete floor-standing direct-reading spectrometer, ultrasonic thickness gauge, ultra-short acoustic thickness gauge, ultrasonic coating thickness gauge, impact testing machine, microcomputer screen display universal testing machine, Blowi hardness tester, and Li-type Hardness tester, torque tester, digital ultrasonic flaw detector, magnetic particle flaw detector, box-type electric furnace, pressure tester, finish comparison block, high temperature red multi-external thermometer, temperature and humidity meter, dehumidifier, portable spectrometer, etc. The company has established a complete information management system such as ERP, and has declared a pilot enterprise for the integration of the two management systems, laying a solid foundation for improving technological innovation capabilities, quality control capabilities and corporate management.

4.5 Safety management of special equipment

The special equipment currently used by the company mainly includes: cranes, elevators, gas storage tanks, etc. According to the "Special Equipment Safety Law of the People's Republic of China", the management is carried out in strict accordance with the requirements of laws and regulations. The company formulated the "Infrastructure and Environmental Control Procedures", established special equipment management related materials, and formulated specifications for the use, calibration, operator qualifications, maintenance and maintenance, and emergency plans of special equipment. According to the requirements, the company conducts regular maintenance, asks a qualified professional organization to conduct an annual inspection and obtain a calibration report; operators must undergo professional training and obtain a certificate issued by a professional organization before they can start their jobs.

5. Product quality responsibility

5.1 Product Quality Commitment

Quality and Integrity Commitment:

The company solemnly promises to the whole society, and self-discipline with this:

1. Establish a system of quality and integrity education and rewards and punishments. Organize employees to learn quality and integrity standards in accordance with system requirements, improve quality and integrity awareness, and make relevant records; implement quality integrity responsibilities in combination with employees' job responsibilities, form quality integrity performance evaluation and rewards and punishment mechanisms, and promote employees to actively participate in the construction of corporate quality and integrity.

2. Establish a quality integrity inspection system. Equipped with qualified or correspondingly capable inspectors in accordance with relevant regulations; conduct strict inspection or verification of raw materials and outsourcing and outsourced parts, and keep relevant inspection or verification records in accordance with regulations; equip with necessary factory inspection equipment, in accordance with standard requirements Carry out strict quality inspections on the final products to ensure that unqualified products do not leave the factory, and keep product inspection records as required; regularly verify or standardize the inspection and testing equipment in use to ensure that the inspection and testing equipment meets the requirements.

3. Establish after-sales service system. Provide product instructions to customers; establish customer files; establish after-sales service network to help customers solve problems encountered during product use within the promised time, properly handle customer complaints and complaints about product quality, and strive to satisfy customers; carry out Customer satisfaction survey, understand customer needs, and continuously improve quality.

4. The company has established an effective recall and traceability system for products involving human health and personal and property safety. Products that are found to be defective can be recalled in time; for product quality accidents, they can be handled promptly and properly, and the relevant responsible persons can be held accountable.

5. Carry out self-discipline activities of quality, integrity, etc. in the form of expressing quality with signs. Express or make public commitments to the characteristics of the raw materials, quality performance, or quality level used in the product that reflect the quality of the product. If the company’s product quality issues lead to domestic and foreign notification, return or destruction, the company voluntarily accepts relevant treatments as required by the state and relevant treaties.

5.2 Product after-sales responsibility

The company has formulated a complete set of rigorous and mature after-sales service system. When there are hidden dangers such as quality and safety of the factory products, it can effectively and quickly trace, repair, replace, recall, etc., to ensure that the related hidden danger products are recalled smoothly, accurately and effectively handled. The company solemnly promises that if there is a quality problem with the company’s products, after a joint investigation by the company and relevant departments, it is confirmed that it is indeed the company’s responsibility, the company will strictly abide by the "Product Quality Law" and other corresponding laws and regulations, and sincerely treat customers apology. The company has never actually recalled due to product quality and safety incidents this year.

5.3 Corporate Social Responsibility

5.3.1 Safety management In order to ensure the effective implementation of the company's investment in safety production, the company established a safety production management committee, implemented a hierarchical responsibility system for safety production management positions, signed safety production responsibility letters, organized safety training, and provided fire protection Safety equipment, regular company-wide safety inspections, formulation of emergency plans, implementation of safety "three simultaneous", etc.

The company establishes the safety responsibilities of various functional departments, and establishes the safety responsibilities of all types of personnel at all levels. The company also formulated the following rules and regulations:

(1) Safety production inspection system;

(2) Safety production education and training system;

(3) Work safety assessment, reward and punishment system;

(4) Work accident management system;

(5) Equipment and facility safety management system;

(6) On-site safety management system;

(7) Electrical safety management system;

(8) Labor protection equipment management system;

(9) Security investment guarantee system;

(10) Safety regular meeting system;

(11) Fire safety management system. At the same time, the company has set up a special expense account for production safety, so that the special funds can be used exclusively. Participate in work-related injury social insurance in accordance with the law, pay work-related injury insurance premiums for employees, and provide employees with labor protection products that meet national or industry standards. Provide three-level safety education and special operation personnel training and education for new employees entering the factory. Statistical Report on Work Injury Accidents Work accidents should be handled in accordance with the principle of "Four Don't Let Go". The company has established and improved safety operating procedures for the post, and trained operators on the safety operating procedures for the post. The company adheres to the occupational health and safety management policy of "compliance with laws and regulations, safe and environmentally friendly operations, and building a beautiful home", fully relies on scientific management, adheres to safety first, prevention first, continuously improves the effectiveness of the management system, and eliminates it to the utmost extent. All kinds of hazards and hidden dangers, avoid and reduce the health and safety of employees and all those who enter the workplace, and damage to the company's property, and strive to improve the company's management level.

5.3.2 Environmental protection The company has identified applicable environmental laws and regulations in daily management, and strictly implemented national, provincial, and municipal environmental protection laws and regulations. The main pollutant is domestic sewage. The company entrusts a third-party monitoring station to inspect the company's sewage, plant noise and unorganized discharge every year. The test results meet the relevant standards and there is no excessive discharge. The solid waste generated in the company's production process is entrusted to qualified enterprises for recycling and disposal, and no environmental pollution incidents occur. The company actively responds to the call of the country, saves resources, promotes cleaner production, and reduces pollutant emissions. The company has passed ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification.

6. Quality risk management

(1) Pre-prevention, do a good job of pre-production preparations. Before the product is officially put into production, a set of preparatory activities must be experienced.

1. Order review. The company organizes review meetings for each order and each contract to determine whether the company's production capacity can be reached, whether the materials can be purchased, whether the price is reasonable, especially the quality, whether it can meet customer needs, and whether it can be tested.

2. Prenatal meeting. Before each production order, we organize discussions on technology, quality, production, property management, etc. The main purpose is to discuss the product structure, style, specification, material performance, manufacturing process, etc., to determine whether the technology can be achieved and whether there is production. Risks, quality issues can be controlled, etc.

3. Trial production. Before mass production, the products are produced in small batches to truly test the feasibility of the theory from practice, and finally determine whether the products can be launched in large quantities, and to find and solve quality problems in time.

(2) Strict management and control to minimize quality risks

Do a good job in quality control, adhere to the one-stop supervision from design and development-raw material procurement-production-inspection to minimize quality risks.

1. Design and development stage. The company always insists that the quality of the product is designed. In accordance with the design and development related systems, we will strive to do a good job in product approval, design review, and design verification. According to design requirements, check the production of samples, find quality problems in practice, overcome quality difficulties, and find out where quality problems are prone to occur.

2. Product production links. High-quality products are achieved by standard and standardized production. The company adheres to the practice of "quality first". The production line has formulated work instructions for each process according to the technical documents of the technical department. Each operator strictly operates in accordance with the technical documents and work instructions, and always adheres to the principles and methods of total quality management. Established a system of first inspection, self-inspection, random inspection, and final inspection (full inspection) to ensure quality assurance in the production process.

3. Quality inspection stage. Quality inspection is the ultimate guarantee for the high quality of products. The inspection link of incoming material inspection-semi-finished product inspection-patrol inspection-final inspection-outgoing inspection has been established, and each link is implemented in accordance with inspection standards.

(3) Actively respond and handle quality complaints in a timely manner

1. In order to ensure the continuous improvement of product quality, improve the company's quality service level, and improve customer satisfaction, the company has established a complaint handling process in accordance with the requirements of the ISO9001 quality management system. The complaint handling process is: when the business receives information that may be a product complaint, it should immediately review or evaluate the information. This information may be the only information of this incident and should be written into the complaint record; determine whether the information constitutes a product complaint, if the information does not constitute a product complaint, no further measures are required; write the details of the complaint into the record ; Investigate product complaints, regardless of whether there is a root cause, the complaint should be investigated to determine whether a non-conformity has occurred, and whether the corrective/corrective measures related to the complaint are appropriate.

2. The company conducts a questionnaire survey on customer satisfaction every year. The survey content includes product quality, delivery date, service and other aspects. Customers evaluate all aspects of product requirements and expectations, and then statistically analyze the data to determine the next One-step quality performance optimization and upgrade direction and sales and service quality improvement goals.

Conclusion of the report

Quality is the foundation of the survival of an enterprise, and the level of quality is a barometer of the overall strength of an enterprise. If an enterprise is to remain invincible in the fierce competition, it must pay close attention to quality and continuously improve its quality management level. Shuangda Co., Ltd. always adheres to the practice of "quality first", takes innovation to promote technological progress as the premise, implements lean production and ensures high quality and efficiency as the key, and establishes an advanced inspection system as quality assurance, thereby establishing an efficient quality The management system establishes the quality concept of all employees.

In the process of quality management, establish a new concept of quality, strictly control the quality gate, promote the construction of quality culture, do a good job in quality publicity, improve employees’ The goal of "manufacturing" domestically leading and world-class continues to work hard.

PRV NEWS:What is the general quotation of hard-sealed fully welded ball valve manufacturers?

NEXT NEWS:social responsibility Report

浙公网安备 33032402002155号

技术支持:温州网站制作-温州中网

浙公网安备 33032402002155号

技术支持:温州网站制作-温州中网